Champion teams work on a wide range of projects, each requiring specific attention to safety. Understanding the challenges associated with different environments, protocols and safety systems helps ensure we perform up to expectations while protecting our most important asset – the safety of one another. Our May 2024 Safety Newsletter focuses on the prevention of swing falls in bridge work, specifically regarding the dangers associated with a personal fall arrest system (PFAS) when the anchor is not directly above a worker.

A swing fall, or pendulum fall, occurs when the anchor point in a PFAS is not directly above a worker’s head, causing a fall to have a horizontal direction. This horizontal movement increases the risk of a worker colliding with surrounding structures or equipment – sometimes at an equivalent speed of 20MPH or more – potentially resulting in serious injuries or fatalities. The velocity and length of the fall increase as the angle from the anchor point increases, which consequently raises the likelihood of impact with objects in the swing path.

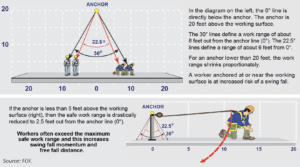

To minimize these risks, work should be conducted as close to directly below the anchor point as possible. Manufacturers of PFAS often recommend maintaining a maximum angle of 30°, with some advising a more conservative angle of 22.5° or less to further reduce risks. (The maximum arc of a swing fall is typically measured by the number of degrees off center from the anchor, added to both sides of the center line.) A safe fall plan establishes a maximum work range from the PFAS anchor point, properly adhered to by the team, and enforced by the appropriate supervisor. (See chart as a basic guideline to determining maximum work ranges.)

[Chart: Setting Maximum Work Ranges]

Overall, proper planning and strict adherence to safety guidelines are critical to preventing swing falls. Meeting and exceeding the recommendations set by various industry organizations, including the Federal Highway Administration, will enhance safety in bridge construction and maintenance operations – and support our continued focus on safety for every employee.

At the beginning of 2024, each member of our IPEC decommissioning/demo team in Buchanan, NY, was challenged to make safety their #1 priority. Though much of the work on this project was a first-time evolution for the team, their proactive approach to identifying potential risks and hazards serves as a true testament to Champion’s safety culture.

Their commitment, communication, and teamwork enabled them to remove 40-ton U3 Feed Water Heaters (FWH) incident- and error-free. The team’s Safety-First attitude not only made the project a success but also reinforced our reputation as an organization that delivers safe, quality work without compromise.

Contact Champion