Underground Tank Removal at Pilgrim Nuclear Station

Plymouth, Massachusetts

The Indian Point Nuclear Power Plant, once a key energy provider in the state of New York, was permanently shut down in 2021 following an evaluation that determined it had exceeded its operational lifespan and could no longer operate safely. The decommissioning of this facility represents one of the most significant nuclear plant closures in the U.S. since the 1980s.

Champion, a seasoned general contractor with a proven track record of fuel removal and decommissioning work alongside Holtec (the current owner of the plant), was selected to lead the decommissioning of Indian Point. Our work includes the removal of nuclear fuel, the removal of spent fuel pool racks, decommissioning of the reactor heads, removal of the circulating water pumps, and the safe handling and disposal of radiological material. This project involves several technical and regulatory challenges, as safety and precision are paramount in decommissioning nuclear facilities.

As the general contractor on this project, we are responsible for overseeing and executing every aspect of the decommissioning process, without relying on subcontractors for key tasks such as reactor head demolition. This includes:

One of the key challenges of this project is the simultaneous demolition of all three reactor heads, which is necessary to optimize efficiency and minimize disruption to the project timeline. Given the size and complexity of the reactor heads, each weighing 122,000 lbs, cutting them apart using a wire diamond saw ensures that workers can remain at a safe distance while reducing the spread of radioactive contamination. This method minimizes worker exposure and ensures that the process remains safe for everyone involved.

As each reactor head is cut into pieces, our team performs dose readings to monitor and confirm that the radiation levels fall within safe and acceptable ranges before the materials are transported for disposal. This careful attention to radiation levels ensures that the public and the environment remain protected throughout the process.

When working with radioactive material, the project area is fully tented to contain any potential contamination within a controlled zone. This also allows for more efficient cleanup once the decommissioning is complete, ensuring the site is restored to a safe and clean state.

Safety is the highest priority throughout the decommissioning process. Every task is carried out in strict compliance with nuclear safety regulations, and we have a team of Subject Matter Experts (SMEs) who oversee operations and equipment maintenance. Our experts ensure that all equipment is properly maintained and that every step of the project is executed following established safety procedures.

Our teams are trained in radiation protection, hazardous materials handling, and emergency response procedures to ensure a quick and effective response in the unlikely event of an incident. This robust safety culture is built into every aspect of the work, from equipment maintenance to worker training and site management.

What sets this project apart is that we are acting as a full-service General Contractor, executing all major tasks directly without the need to subcontract for the demolition and removal of the reactor heads. This gives us full control over the project’s efficiency, safety, and quality. Our extensive experience in working with Holtec on similar decommissioning projects has solidified our role as a trusted partner in the nuclear industry.

The decommissioning of the Indian Point Nuclear Power Plant is a complex, high-stakes project that requires the highest levels of safety, precision, and efficiency. By applying advanced techniques like diamond wire cutting and maintaining strict safety protocols, we are able to safely manage the risks associated with radioactive materials and ensure a successful decommissioning. Our role as the general contractor overseeing all aspects of the decommissioning—from fuel removal to reactor head demolition—sets us apart as a leading contractor in this field.

We look forward to completing this project by the end of 2025, ensuring that the site is fully decommissioned, safe, and ready for its next phase.

Customer: Indian Point Nuclear Power Plant

Partner: Holtec

Completion Date: (Projected) End of 2025

Size: 3 reactor heads, 122,000 lbs each

Fuel Removal

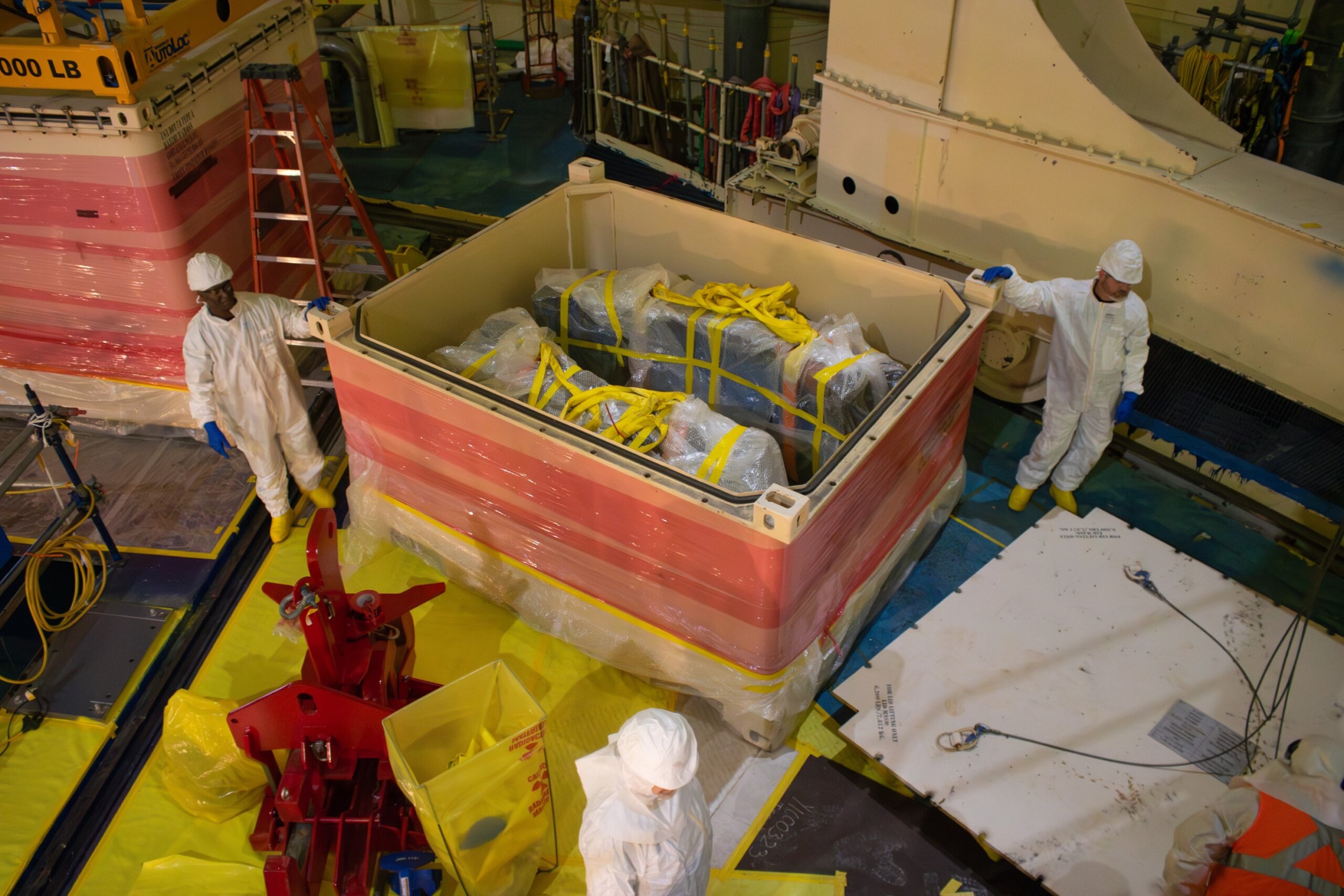

Spent Fuel Pool Rack Removal

Reactor Head Demolition

Removal of Circulating Water Pump

Radiological Waste Management

Lead & Asbestos Removal

Electrical Services

Decommissioning

Champion acted as a full-service General Contractor on this project