Underground Tank Removal at Pilgrim Nuclear Station

Plymouth, Massachusetts

The Mercedes-Benz Stadium, home to the Atlanta Falcons and Atlanta United FC, is the Southeast’s premier stadium. Notable for its aperture-style retractable roof, it is also the first LEED Platinum certified professional sports stadium in the United States, powered largely by design innovations that conserve water, energy, and light. Since it opened in late 2017, the stadium has hosted Super Bowl LIII, the College Football Playoff National Championship, SEC Championships, the Peach Bowls, and countless concerts. To date the record attendance at the stadium is a staggering 79,330 people who turned out to watch and be a part of the 2022 Peach Bowl.

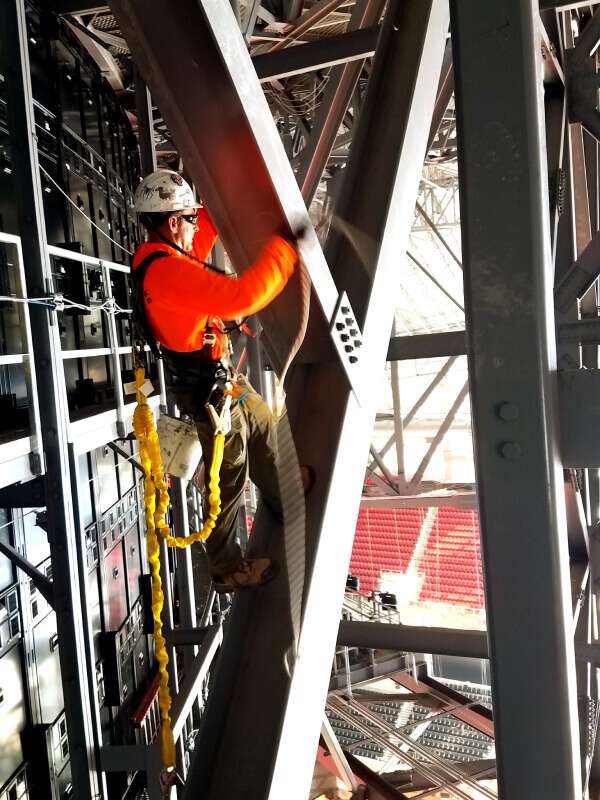

Every aspect of the design and construction of the Mercedes-Benz Stadium is state-of-the-art. The structure features Mega Columns and extremely long truss spans that hold up the roof. Much of the steel, manufactured by Canam Steel Corporation, was shop blasted and primed. Eighty percent of all steel painting, however, was performed onsite by Champion after the steel was erected. The requirement to coat the steel onsite—in areas not designed to be entered after erection—demanded a complex access strategy and innovative painting techniques.

Champion accessed the overhead steel structure using a swing scaffold, Spider baskets, aerial lifts, and SPRAT-certified rope access crews with unparalleled steel climbing expertise. Employees frequently worked at heights that soared over two hundred feet. Challenged with an extremely aggressive schedule, Champion crews involving over 100 individual craft specialists worked day and night to coat the steel as it was being erected. Because the successful coordination of resources was paramount to delivering the project as soon as possible, Champion maintained a fluid communication process among the dozens of other trades laboring onsite to complete their scope of work.

When asked about Champion’s contribution to the project, Kyle Hough, COO of Champion Specialty Services, said: “This project is one that I am proud of. It was a very demanding project that required a lot of perseverance for several years and we consistently executed at a high level making it a successful project.”

Today’s stadium design must account for more than simple attendee management. Owners and fans seek to create inspired community experiences made possible by the most cutting-edge and responsible construction practices available. In a crowded marketplace, the Mercedes-Benz Stadium outperforms much of its competition in terms of sustainable design and construction expertise—all of which were made possible by the elite craftwork contributed by every trade associated with delivering the project, including Champion. An integral partner in bringing the Mercedes-Benz Stadium to timely completion, Champion is now known across the industry as a trustworthy, innovative partner for designers, general contractors, and fabricators who are involved in building or renovating a complex steel-supported sports stadium.

This was Champion’s third project with Canam Steel. Both parties worked closely with general contractor HHRM to ensure that the coating work was scheduled and completed in the best capacity and to the highest standards, in keeping with the overall goals and expectations of the client, the state of Georgia, and the project architect, HOK.

Customer: AECOM

Completion Date: May 2018

Size: 5,500,000 SF

Specialty Services

Aerial Drone Inspection

Stadium

Coatings

Corrosion Control